Press Release: Wagler’s Twin-Charged, Nitrous-Assisted DX500 Billet Duramax Unveiled at SEMA

Las Vegas, NV – November 1, 2016 – WAGLER COMPETITION PRODUCTS (WCP) continues to push the limit of diesel motorsports with their DX500 billet Duramax engine. Unveiled at the 2016 SEMA Show, the DX500 is built to handle extreme power levels and every piece is held together by the best fasteners on earth. It’s only natural that the DX500 is on display in the Automotive Racing Products (ARP) booth, #22525 in the central hall.

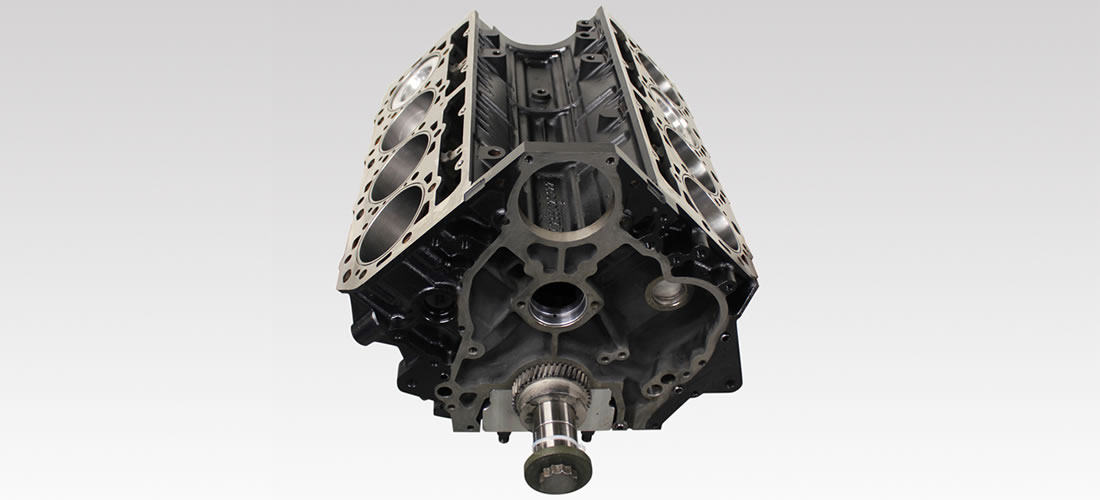

WCP’s DX500 is the first-ever all billet Duramax engine. It was designed and machined in house by Wagler Competition Products specifically to meet the extreme power demands of top level diesel competition. The WCP DX500 will be offered to the public with many different options to choose from, but WCP held nothing back for the very first version by using every power-adder at their disposal. At first glance this may seem like overkill, but this particular DX500 will be the same engine Wagler installs in their 2017 Ultimate Callout Challenge (UCC) entry called “The Shop Truck”. The Ultimate Callout Challenge is an invitational contest of diesel glory where the only rules are the laws of physics – there’s no better venue to push the DX500 prototype to the limit.

The 500 cubic inch DX500 utilizes the best components and technology available in the racing industry. The billet Duramax block, billet heads with ductile iron insert, and billet intake assembly were manufactured by Wagler Competition Products. The rotating assembly consists of: a Winberg crankshaft, WCP rods, Ross pistons, Trend wrist pins, and a Total Seal ring set. The DX500 uses an innovative Comp Cams camshaft with a roller cam bearing and Trend pushrods. Everything is held together by ARP fasteners. Fuel for the DX500 is provided by a custom system from S&S Diesel Motorsport, the leader in electronic diesel injection, and includes triple high pressure CP3 fuel pumps, precision calibrated injectors, media honed fuel rails, and a Bosch Motorsport ECU with S&S calibration. The UCC edition DX500 also has a methanol injection system by Engler and a Waterman pump to feed it. All of that fuel needs plenty of air and Wagler has chosen to use a combination of the best power adders in existence: a PSI screw blower and twin Precision Turbo & Engine Pro Mod 102 turbochargers. The screw blower will get things going and the turbos will feed generous amounts of air through the Vibrant piping into the custom intake, post-supercharger. Power management will be of utmost importance and Wagler is utilizing twin PTE 66mm wastegates to keep the air under control. As if that is not enough, the UCC-version of the WCP DX500 will also be nitrous assisted. All of the power adders and different injectables must work as a system, and that will be handled by the Bosch Motorsport ECU and the wizards at S&S Diesel Motorsport.

General production DX500s are not available yet, but Wagler Competition Products will put the UCC DX500 through the wringer to make sure all the proper testing has been done before they become available for purchase.

About Wagler Competition Products:

Based out of Odon, IN, Wagler Competition Products was founded in 2011 and has been setting the standard and pushing the limits in diesel performance ever since! Parts offerings include Duramax cylinder heads, intakes, intercooler piping, hardcore engine parts and components including pushrods and rotating assemblies, and so much more. For more information, visit online at WaglerCompetition.com and “like” Wagler Competition Products on Facebook at facebook.com/WaglerCompetitionProducts.