Republished from DieselWorldMag.com – All engines, diesels included, are essentially giant air pumps when you think of them in their most basic form. The pistons move up and down in a cylinder, drawing in and pushing out air and combusted fuel to make power. The gatekeeper becomes the cylinder head and intake and exhaust valves.

Improving the airflow in an engine increases efficiency, and consequently performance in terms of more horsepower and torque from improved airflow into and out of the cylinder along. The improved efficiencies have been demonstrated on the outside of the engine with the addition of such aftermarket goodies as the addition of an aftermarket intake and exhaust system, and turbo upgrades.

Once these bolt-on upgrades are done, what other area can improve engine breathing? The answer is cylinder head upgrades. In the performance arena, cylinder heads mods, such as CNC porting, are a very common upgrade in the diesel world. The gas folks have enjoyed a wide selection of aftermarket cylinder head upgrades to choose from but there were few aftermarket performance cylinder heads available for us diesel guys. Jeremy Wagler of Wagler Competition Products set out to change that.

Wagler is a long-time gearhead with many years of diesel performance experience. In 2011, he established Wagler Competition Products (WCP) to develop a performance aftermarket cylinder head for the GM Duramax diesel engine. He teamed with one of the most famous cylinder head manufacturers in the gasoline world, Brodix, to cast a replacement aluminum cylinder head for the Duramax engine that would be able to serve as both a replacement alternative to factory heads and a high-performance head capable of supporting high-power competition engines. The heads are cast from virgin A356-grade aluminum alloy by Brodix in their Mena, Arkansas foundry. They also handle basic machining for mating surfaces, injector mounts, valve guide pockets and spring seats to deliver great “As-Cast” performance out of the box before final machining and assembly at Wagler Competition Products in Odon, Indiana.

The heads can be configured in an almost limitless manner ranging from stock replacement, reusing original valves, springs and hardware to full-race with larger valves, bronze guides and high-performance beehive springs. Wagler also incorporates a relocated valve centerline that allows larger valves to be used and unshrouds the valves for more performance, and better airflow and swirl than factory heads.

Even with stock-sized valves, the WCP heads flow more air than factory heads and larger valves flow even more! Even though it looks a lot like a stock Duramax head and bolts into place like a stock head, it’s a fresh ground-up design that removes many of the factory weaknesses and improves upon the head with larger ports to take full advantage of aftermarket performance parts and fuel system upgrades.

For LB7 applications, Wagler incorporated the injector cups into the casting to remove the need for factory or aftermarket cups that are prone to leaking. In addition to valves, springs, retainers and guide options, WCP also offers many levels of porting options. Using one of their two in-house, multi-axis CNC machines they can cut a relief to work with the factory clamshell intake manifolds. The ports can also be hand blended for increased flow over the As-Cast versions or treated to full-blown five-axis CNC porting with hand polishing that provides the ultimate flow for a Duramax head. Of course, the port and polish work will increase the flow when using stock-sized valves but will be even better with larger valves.

The WCP S-Series heads are designated as stock replacement heads while the X-Series heads are for competition use. Regardless of the designations the heads all come from the same Brodix castings. The differences lie in the valve sizing and optional porting as well as the valvetrain hardware like valves, springs, guides and retainers. Customers wanting entry-level WCP Duramax heads can opt to reuse their valve train hardware including valves, springs, retainers and keepers. Using the factory 33mm intake and 31mm exhaust valves, Wagler measured around 60 more CFM of airflow per cylinder on the intake and about 50 more CFM per cylinder on the exhaust. So with a basic head swap the Duramax engine is capable of ingesting an additional 480 cubic feet of air per minute and expelling an additional 400 CFM. Stepping up to larger 36mm intake valves, 35mm exhaust valves and porting showed nearly 120 CFM more airflow on both the intake and exhaust verses a stock GM LMM head.

It’s easy to see that this upgrade has a lot of potential to make more power, especially when you consider that with the ported head and larger valves the engine could flow 960 CFM more in and out of the engine. To put that into perspective, 960 cubic feet of volume is equal to the volume of a room that is 10-foot by 10-foot by 9.6-feet tall! With proper supporting modifications, Wagler and his team have seen increases of 200-300 horsepower on high-horsepower competition engines by swapping production GM heads for a set of WCP heads.

For those wanting even more flow, WCP can build the heads with 38mm intake and 37mm exhaust valves that are 15- and 19-percent larger than the stock valves respectively. With a stock 6.6L Duramax cylinder bore you can run up to 34/33mm valves while larger sizes require boring the block for proper valve clearance. Thanks to larger intake and exhaust parts and runners all of the WCP heads, flow more air than factory Duramax heads.

It’s noteworthy from looking at the flow bench data that the GM heads reach their flow limits right around .300 inches of valve lift, meaning that additional lift from an aftermarket cam will do little to provide more airflow with stock heads. As a contrast, the WCP heads outflow the factory heads in the lower lift range, but also keep flowing more air as the lift increases making them perfect for competition applications where high-lift camshafts are used.

The new Wagler Competition Products cylinder heads bolt directly to factory Duramax engine blocks and can be configured to work with Duramax V-8s produced from 2001 and up. They work with all of the factory provisions and can be used as a factory replacement head for Duramax engines. Factory rocker arms and bridges are still used to actuate the valves so there’s no need for additional custom components. Intake ports and mounting surfaces can be ported and machined to optimize airflow with factory or aftermarket runner-style intake manifolds.

We were invited up to WCPs facility to check out the cylinder heads in person, watch the machining processes and see flow bench testing on their SuperFlow SF-1020 flow bench. Seeing the high-tech shop and machining capability on the outskirts of a small rural Indiana town in Amish country complete with horses and buggies roaming the roads is an odd sight for sure, but the capabilities at WCP are quite impressive to say the least. In addition to their Duramax heads they also do porting on all makes of cylinder heads for diesels.

Wagler and his crew also design and build custom billet aluminum intake manifolds as well as complete competition engine packages from balanced rotating assemblies to high-end fuel systems. Wagler Competition Products’ three-axis Haas VF3 CNC mill is used primarily for fabrication of billet aluminum parts like intake manifolds and such while their five-axis Centroid A560XL CNC tackles the intricate CNC porting of cylinder heads. A trio of Rottler machines are used to complete the heads, including machining the valve guides and seats (at multi-angles), multi-angle valve refacing and cylinder head surfacing. The Rottler surfacing machine is also used to true and cut block and manifold surfaces.

In the near future, Wagler plans to add an engine dyno to his already stout arsenal of shop equipment so that he can further refine and test not only his cylinder heads but also the complete engine combinations that they offer.

Prices for the cylinder heads range from $3,250 for bare castings that you install your own components into, all the way up to $8,905 for complete assembled big-valve CNC-ported heads ready to bolt onto your competition engine.

Whichever route you decide to take, if your Duramax is in need of new heads or you’re looking to squeeze every last bit of power out of your competition engine you owe it to yourself to check out the Wagler Competition Performance heads.

While we were at the shop we also followed along as Wagler installed a set of heads on a LMM GMC along with an injector upgrade, and we’ll bring that installation to you in next month’s issue.

| Valve Lift | Stock GM Head | Stock with Clamshell Intake | WCP “As-Cast” | WCP “As-Cast” with Clamshell Intake | WCP Ported 36/35mm Valves | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Int CFM | Exh CFM | Int CFM | Exh CFM | Int CFM | Exh CFM | Int CFM | Exh CFM | Int CFM | Exh CFM | |

| .100 | 86.3 | 70.2 | 82.1 | 65.5 | 89.0 | 73.8 | 88.1 | 72.0 | 91.9 | 89.5 |

| .200 | 151.7 | 130.0 | 145.9 | 125.4 | 162.9 | 135.5 | 164.3 | 133.8 | 175.6 | 163.0 |

| .300 | 177.1 | 146.8 | 168.8 | 144.6 | 214.8 | 163.6 | 206.9 | 162.5 | 243.7 | 198.2 |

| .400 | 180.5 | 149.8 | 176.3 | 147.9 | 234.6 | 179.2 | 221.1 | 178.1 | 267.1 | 228.4 |

| .500 | 183.6 | 149.5 | 177.1 | 148.1 | 239.2 | 189.2 | 226.6 | 188.2 | 277.7 | 245.4 |

| .600 | 182.9 | 149.4 | 177.2 | 148.4 | 244.2 | 196.0 | 229.5 | 195.3 | 289.7 | 254.4 |

| .700 | 183.3 | 149.5 | 176.5 | 148.4 | 249.1 | 200.4 | 233.2 | 199.7 | 296.8 | 260.9 |

| .800 | 300.1 | 264.0 | ||||||||

One side of the CNC machine shop is dominated by the large five-axis Centroid A560XL that is used to perform complicated CNC machining (like head porting) that would be impossible with a three-axis machine.

One side of the CNC machine shop is dominated by the large five-axis Centroid A560XL that is used to perform complicated CNC machining (like head porting) that would be impossible with a three-axis machine.

Alex Divine is the lead machinist at WCP and oversees the CNC porting of the cylinder heads. Here he’s securing a head to the machining plate inside the large machine.

Alex Divine is the lead machinist at WCP and oversees the CNC porting of the cylinder heads. Here he’s securing a head to the machining plate inside the large machine.

Since the machining plate can rotate and the head can swivel, the tool is able to reach deep inside the head to get maximum airflow from the CNC porting process.

Since the machining plate can rotate and the head can swivel, the tool is able to reach deep inside the head to get maximum airflow from the CNC porting process.

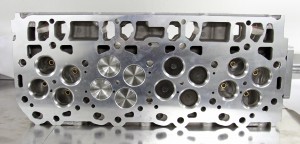

Looking inside a machined head we can see that the bowl below the valves are machined to maximize airflow. Notice the bronze valve guides on the exhaust side are machined as well to prevent the tip of them from overheating from the hot exhaust gasses of a performance Duramax engine.

Looking inside a machined head we can see that the bowl below the valves are machined to maximize airflow. Notice the bronze valve guides on the exhaust side are machined as well to prevent the tip of them from overheating from the hot exhaust gasses of a performance Duramax engine.

The intake ports and runners are machined beyond visible depth or reach by hand to make sure airflow is optimized into each cylinder.

The intake ports and runners are machined beyond visible depth or reach by hand to make sure airflow is optimized into each cylinder.

On the exhaust side of the head you can see all the way into the valve pockets through the machined port and runner.

On the exhaust side of the head you can see all the way into the valve pockets through the machined port and runner.

Here a stock head out of an LMM (complete with EGR soot stains) is sandwiched by a pair of “As-Cast” S-Series Wagler Competition Products heads. The top head has the optional clamshell intake relief machined into the intake surface, note how well the machining follows the path of the clamshell manifold as you can see by comparing it to the stock head.

Here a stock head out of an LMM (complete with EGR soot stains) is sandwiched by a pair of “As-Cast” S-Series Wagler Competition Products heads. The top head has the optional clamshell intake relief machined into the intake surface, note how well the machining follows the path of the clamshell manifold as you can see by comparing it to the stock head.

Looking closely at the exhaust side of the “As–Cast” WCP head (top) versus the factory head it’s easy to see the size difference in the ports as well as how closely the WCP port matches the exhaust manifold gasket.

Looking closely at the exhaust side of the “As–Cast” WCP head (top) versus the factory head it’s easy to see the size difference in the ports as well as how closely the WCP port matches the exhaust manifold gasket.

With the EGR soot cleaned you can clearly see the size difference of the WCP intake ports (on top) compared to the tiny factory ports in the stock head.

With the EGR soot cleaned you can clearly see the size difference of the WCP intake ports (on top) compared to the tiny factory ports in the stock head.

After the valve seats are installed then cut for the multi-angle valve job, Jeremy Wagler hand blends the transition from the valve seat to the bowl for best flow.

After the valve seats are installed then cut for the multi-angle valve job, Jeremy Wagler hand blends the transition from the valve seat to the bowl for best flow.

Wagler then machines the deck surface to set the valve face to deck face surface clearance to make sure that the valves do not have a nasty run-in with the pistons.

Wagler then machines the deck surface to set the valve face to deck face surface clearance to make sure that the valves do not have a nasty run-in with the pistons.

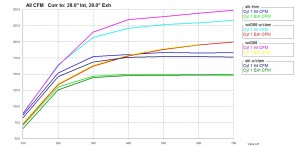

Looking at the flow bench data on this graph you can see the comparison between individual cylinder airflow of a stock LMM head with and without the intake clamshell installed verses a WCP head with and without the clamshell. Notice that the airflow keeps rising with valve lift on the WCP head while the LMM head flattens out at about .300-inch lift. Flow bench testing was done using the same valves in each head so the performance differences are directly attributed to the difference in the head design.

Looking at the flow bench data on this graph you can see the comparison between individual cylinder airflow of a stock LMM head with and without the intake clamshell installed verses a WCP head with and without the clamshell. Notice that the airflow keeps rising with valve lift on the WCP head while the LMM head flattens out at about .300-inch lift. Flow bench testing was done using the same valves in each head so the performance differences are directly attributed to the difference in the head design.

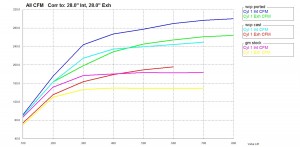

This graph shows the differences between a stock GM head, a WCP As-Cast head with stock-sized valves and a CNC-ported WCP head with larger 36mm intake valves and 35mm exhaust valves. Notice that there is nearly 100 CFM more airflow at .500 lift with the ported head and about 60 CFM additional with the As-Cast head. Those are large performance differences that will allow you to get much more air in and out of your engine for better performance and efficiency.

This graph shows the differences between a stock GM head, a WCP As-Cast head with stock-sized valves and a CNC-ported WCP head with larger 36mm intake valves and 35mm exhaust valves. Notice that there is nearly 100 CFM more airflow at .500 lift with the ported head and about 60 CFM additional with the As-Cast head. Those are large performance differences that will allow you to get much more air in and out of your engine for better performance and efficiency.

Wagler uses his SuperFlow flow bench to precisely measure and verify the performance gains of the cylinder heads making precision adjustments to the valve opening before each measurement.

Wagler uses his SuperFlow flow bench to precisely measure and verify the performance gains of the cylinder heads making precision adjustments to the valve opening before each measurement.

The WCP heads are hand assembled in the engine assembly clean room.

The WCP heads are hand assembled in the engine assembly clean room.

Looking at the deck surface of this big valve head we slid a set of stock valves into the third cylinder position so that you could easily see the difference in valve size between the stock valves and the oversized stainless steel intake and Inconel exhaust valves. They are also shown on the workbench with the intake valves on the left and exhaust valves on the right.

Looking at the deck surface of this big valve head we slid a set of stock valves into the third cylinder position so that you could easily see the difference in valve size between the stock valves and the oversized stainless steel intake and Inconel exhaust valves. They are also shown on the workbench with the intake valves on the left and exhaust valves on the right.

Wagler uses an Intercomp scale to measure the spring pressure at installed height to optimize valvetrain performance and minimize valve float at high rpm.

Wagler uses an Intercomp scale to measure the spring pressure at installed height to optimize valvetrain performance and minimize valve float at high rpm.

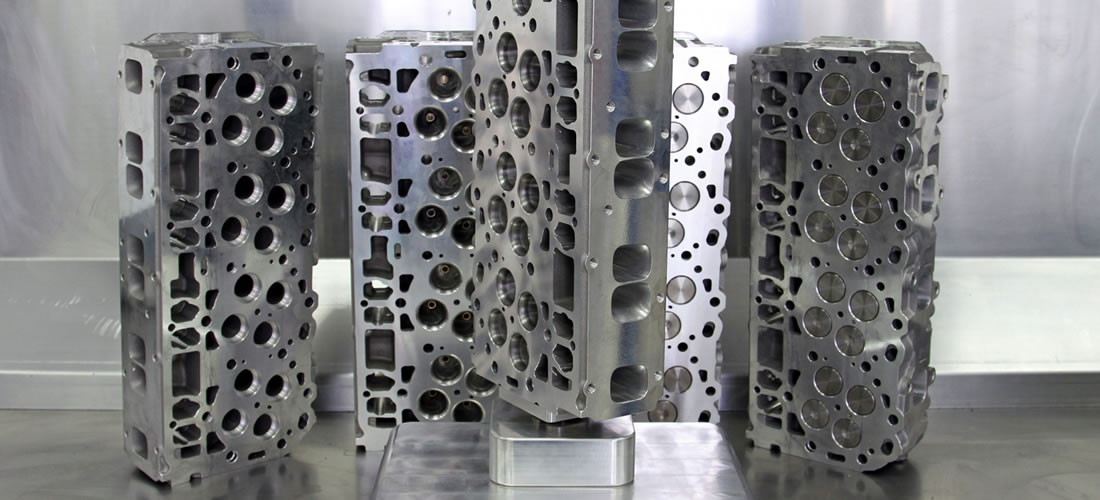

Here are a few of the WCP heads shown alongside a stock GM head and a modified GM head. If your performance budget does not allow for a new set of WCP heads they can also modify your stock heads to make some improvements in airflow.

Here are a few of the WCP heads shown alongside a stock GM head and a modified GM head. If your performance budget does not allow for a new set of WCP heads they can also modify your stock heads to make some improvements in airflow.

We caught this shot of Devine running the lower portion of an intake manifold on the CNC.

We caught this shot of Devine running the lower portion of an intake manifold on the CNC.

The finished manifold looks like this one that will also get an air-to-water intercooler between the upper and lower halves of the manifold.

The finished manifold looks like this one that will also get an air-to-water intercooler between the upper and lower halves of the manifold.